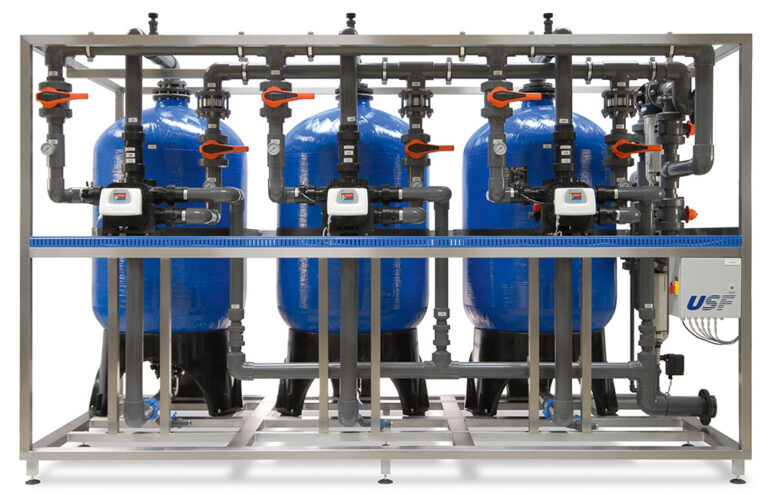

The USF filter systems function using cartridge filtration or based on a multimedia filter and purify up to several hundred cubic meters per hour, with filtration down to 5 µm possible. Control is achieved using central control heads or – especially in large systems – via PLC and individual valve control. For the piping materials, we use plastics (PVC, PP, PVDF) or stainless steel; the filter tanks are also optionally available in stainless steel.

Activated carbon filters are used for chlorine removal, cleaning small quantities, but also up to several hundred cubic meters of water per hour. Here, too, control is via central control heads or PLC with individual valve control. Patented UV systems with UV sensors measure UV transmission and UV intensity.

During UV treatment, chlorine is 100 percent removed from the water. UV disinfection reduces bacteria by a factor of 106, which means that with a feed of 1,000,000 CFU/ml, the value after disinfection is only 1 CFU/ml.

Special filter stations are used for iron and manganese removal. Here, too, both small quantities and several hundred cubic meters per hour can be cleaned.

Control is via central control heads or – in the case of large systems – via PLC and individual valve control. For the piping, we use plastic (PVC, PP, PVDF) or stainless steel; the filter tanks are also available in stainless steel.