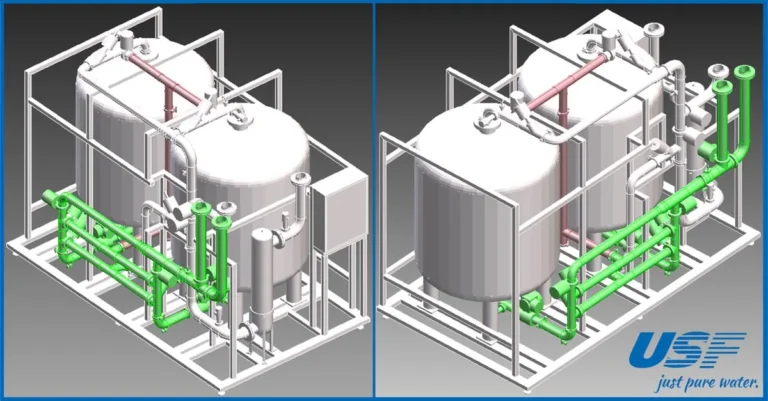

The USF Water Group has completed the engineering and 3D modeling of two activated carbon filter systems, each with a flow rate of 60 m³/h. Both systems are manufactured entirely in AISI316L/1.4404 stainless steel to allow hot water sanitization of the systems.

This minimizes the risk of microbiological contamination.

The filter stations will be delivered to a Hungarian brewery in August 2020. We will keep you updated.